Propeller Repair & Tuning

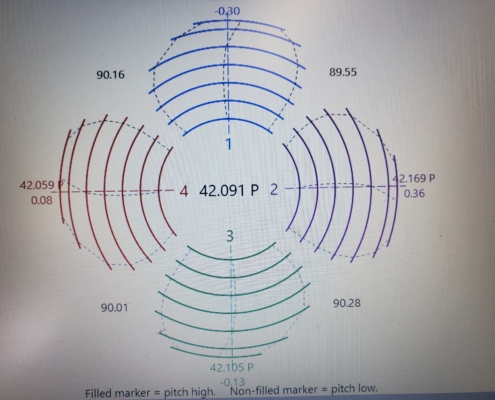

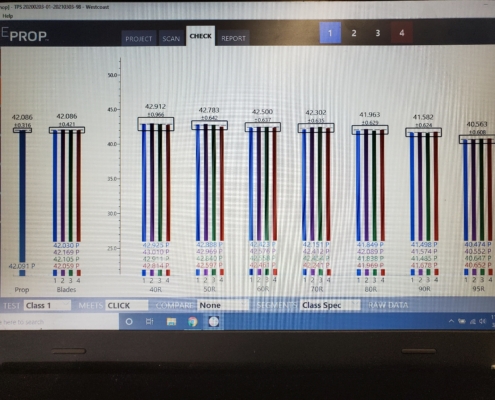

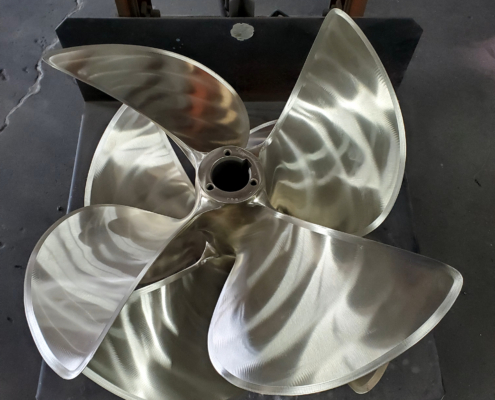

We specialize in precision repairs on Bronze, Nibral, Stainless Steel and the occasional aluminum propeller. Larger props are digitally scanned with a Linden DDS and analyzed using Hydrocomp’s industry leading True Prop Software. This allows us to evaluate the propellers condition before, during and upon completion of the repair process following ISO 484 standards criteria. The smaller propellers are repaired using custom CNC machined Pitch Blocks as a reference to ensure that consistent and accurate tolerances are maintained.

Balancing

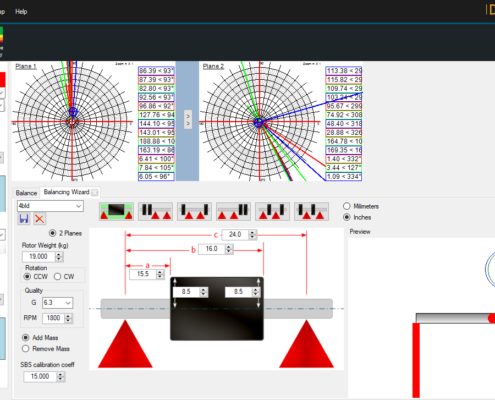

We utilize both Static and Dynamic Balancing methods to ensure smooth, trouble free drivetrain operation. High speed Dynamic Balancing allows us to identify issues that are only detectable while the propeller is in motion. Specialized sensors collect and feed data to our software that allows us to pinpoint the exact position that needs attention. An accurate balance meeting the ISO 1940/1 G6.3 standard guarantees vibration free, quiet and efficient operation.

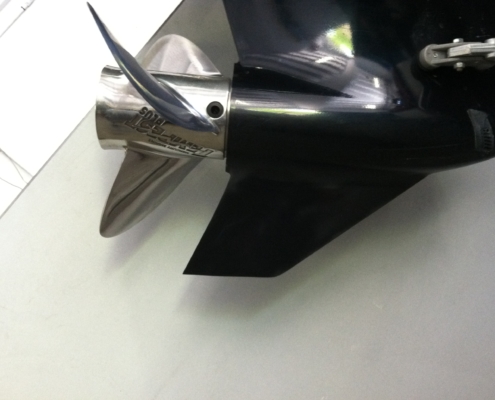

Skeg Repair

Over the years we have successfully repaired hundreds of damaged skegs on outboard engines and sterndrives. We have a large collection of templates that allow us to replicate the profile of the original product. Our experience and methods allow us to safely weld while the gearcase contents remain intact. Repairs can be performed on the boat, without removing the lower unit. The end result is a strong, color matched, like new skeg. You can forget the incident ever happened!

Choosing the right size

Finding the perfect propeller for your application can be a tricky task. We rely on experience and technology to help match the prop to the craft. Hydrocomp’s Prop Expert Software is a powerful tool for the sizing and analysis of propellers for work boats and pleasure craft. It provides the tools needed for the proper selection of propulsion system components – engine, gear and propeller.